-

Call us

262-947-0707

Call us

262-947-0707

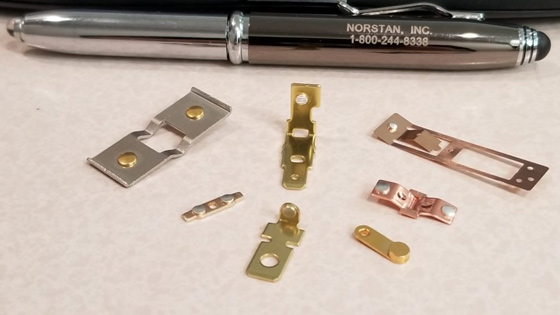

Metal stampers are using high-speed presses and stamping dies to form metal strip into more precise complete and semi-complete parts than ever before. New developments in precision metal stamping can quickly and accurately accomplish complicated stamping applications by using several drawing, folding, stamping, and piercing techniques to their advantage.

Precision stamping comes with a host of unique benefits. This highly automated process reduces labor costs, especially as production volumes increase. This makes metal stamping the method of choice for producing large volumes of metal products.

Advances in stamping technology have resulted in the growth of precision stamping, which can use tools to achieve highly accurate parts. This method is a great way to design:

Many technological advances have improved the way metalworkers carry out precision stamping. Below are a few ways manufacturers now achieve higher levels of accuracy in their finished parts:

Many companies use metal stamping to carry out prototyping and testing. Computer-programmed stamping equipment can rapidly incorporate design changes into the product, allowing you to create several different variations of a part within 1–2-day turnarounds.

A die guides the stock prototype material through the manufacturing process. Manual or automatic feeders move the work piece through each station, delivering a complete product at the end-stage. These automation capabilities mean that you can use progressive strip prototyping to make small parts to tight tolerances with quick turnarounds as there are much fewer opportunities for human error to occur during manufacturing.

This process moves individual prototype parts manually from station to station. Each station either forms or blanks the piece according to programmed instructions. This method reduces tooling costs if the company maintains a standard design.

Norstan, Inc. continuously looks for new ways to improve and refine our processes and products. We also seek to implement the most sustainable manufacturing practices possible, working to reduce our energy usage and waste output.

If you would like to learn more about our precision metal stamping services, contact us today.